Constructed wetlands for olive mills

Wastewater generated by olive mills need to be treated when is neither possible the discharge in sewer nor the field application. In these cases, constructed wetlands are starting to be considered as a nature-based option for olive mill wastewater treatment.

Advantages

- suitable for small/medium mills without

- sufficient land for fertigation

- simple operation and maintenance

- no odour issues

- possibility to discharge in water bodies

- possibility to avoid the installation of

- accumulation tanks, treating the olive mill wastewater also in oil production season

- possibility to recover the concentrate

Constructed wetland for olive mill

Several experiences on the use of constructed wetland (CW) for olive mill treatment are from Greece. Heroyvim et al. (2011), Michailides et al. (2015) and Tatoulis et al. 2016 tested the combination of trickling filters and tertiary treatment with constructed wetlands (vertical flow, free water surface, horizontal flow plus electro-oxidation). Grafias et al (2010) studied the combination of electro-oxidation with vertical flow systems. Stabilization pond as primary treatment and CW for further treatment stages were investigated by Gikas et al., 2013. Finally, Kapellakis et al. (2012) have studied the option of free water systems fed with olive mill wastewater diluted at a ratio of 1:10. Greek experiences have shown high removal efficiencies: organic load 54-94%, TKN 44-98%, SS 52-83%, and phenols 60-95% (Masi et al., 2017).

Another option is to adopt total evaporative systems, without discharge of wastewater.

Recent innovative options are the use of evaporator-condenser plus constructed wetland. This combination was tested by Alfa Laval, azienda leader firm in the field of evaporative systems, together with the University of Florence and IRIDRIA S.r.l., in charge of wetland systems. The most important results of these tests were (Masi et al., 2014):

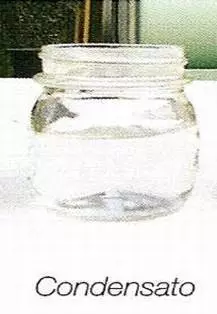

optimal treatability of the condensate with nature-based solutions, up to the water quality standards for discharge in water bodies according to Italian law

no need of accumulation tank to feed the evaporator

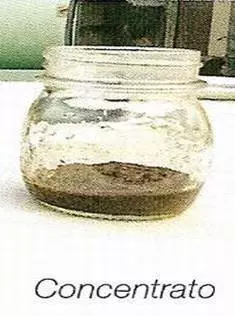

potential reuse of the concentrate as organic-rich amendment

|  |  |

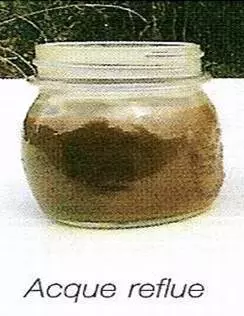

live mill wastewater (left), concentrate (centre) and condensate effluent from the evaporator-condenser plus CW tested by IRIDRA in collaboration with the University of Florence for the olive mill Santa Tea Reggello (FI, Italy)